Metrology

Polis Precis has at your disposal a fully air-conditioned department of dimensional controls.

All the tools are check before the shipment

A complete dimensional control is done on every part. A control report is sent at the customer’s request.

We have different ways of control on the same machine:

MACHINE PARK :

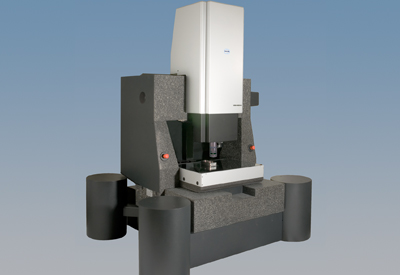

1 Videocheck IP 400 3D: High accuracy fixed-bridge type multi-sensor CMM. Length measuring deviations are lower than 0.5µm.

Available Measuring Sensors: Werth image processing (IP) video sensor, Werth laser sensor, touch trigger and dynamic scanning probes, Werth Fiber Probe, Werth Contour Probe, BestFit of contours after wire EDM.

Applications: Micro components, miniature gears, gauges, length standards, etc.

Temperature-insensitive

Every parts are inspected on every step of production according a self-checking protocol. We work on average at 90% of quality assurance with our customers.

Max Travel: L400 x l400 x H250

1 CNC 4-axis contour and roughness measuring device

Contour and roughness measuring with highest accuracy in the range of 200 x 205 mm (X, Z) and 20 mm (Y) 20 mm (Y) optimised for production measurement:

- Autocalibration as standard feature

- Impossible-to-confuse USB probe arms

- Automatic zenith search in X and Y direction

- 3D evaluation software for contour and roughness

-

- 1 Mesuring column

- 1 TESA-VISIO Max. Travel : X/Y/Z (mm) – 200 x 100 x 150

- 2 Optical glasses

- 1 profile projector

+ Miscellaneous digital control machines with an accuracy of µ