High-Precision Grinding

Flat grinding, cylindrical grinding and JIG grinding on steel, carbide and ceramic tools.

MATERIALS

Carbide: tungsten carbide (all grades), boron carbide, silicium carbide …

Ceramics: Si3N4, ZrO2 and other grades

Sintered and hardened steels

Sparkal and copper for the electrodes

Tungsten

Aluminium

Titanium

Tantalum

PTFE + Carbon

TNA

Bronze

MACHINE PARK :

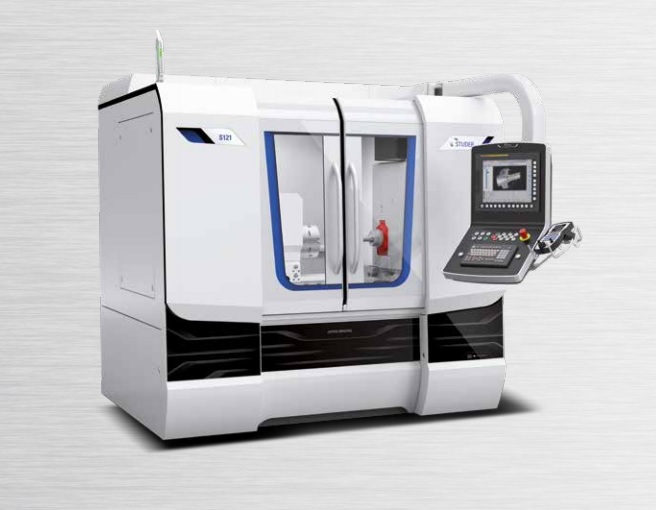

High-Precision Cylindrical Grinding

2 Studer CNC universal internal and external cylindrical grinding machine for medium-sized workpieces in individual and small batch production.

The ideal machine for internal, face and external grinding of chuck components with high-precision axis drives with linear motors and a swivel-in dressing unit.

Perfect for the cylindrical dies which require high precision radius.

Automatic control measurements directly on the machine

Max. Travel: Ø360X300 mm

Swiveling Range B: 180 °

Swiveling Range C: ∞ °

C-axis for the workhead for form and thread grinding

– Roughing and finishing on carbide parts

– dies grinding with radius and cones

High-Precision Jig Grinding

1 Hauser CNC high precision jig grinding machine

Max. Travel X,Y : 500 x 300 mm

Perfect for grinding complex shapes with high degrees of accuracy.

Cylindrical Grinding

- 2 GER CNC cylindrical internal-external grinding Max. Travel: Ø350 X 600 mm

- 1 Tacchella cylindrical external grinding Max. Travel: Ø255 X 400

- 2 Ewag 7 axes WS 11 grinding

Rectification Centerless

- 1 Malcus centerless grinding machine

Flat Grinding

- 1 1430 Jones & Shipman flat grinding machine Max. Travel : L450 x l150 x H457

- 5 540X Jones & Shipman automated flat grinding machines

- 1 540 H visu 2 axes Heidenhain Jones & Shipman flat grinding machine

- 1 OKAMOTO precision surface grinding machine.

Maximum dimension of the part : 800 X 400 X 85